-

Product Overview

-

Product Details

-

Data Download

-

Related Products

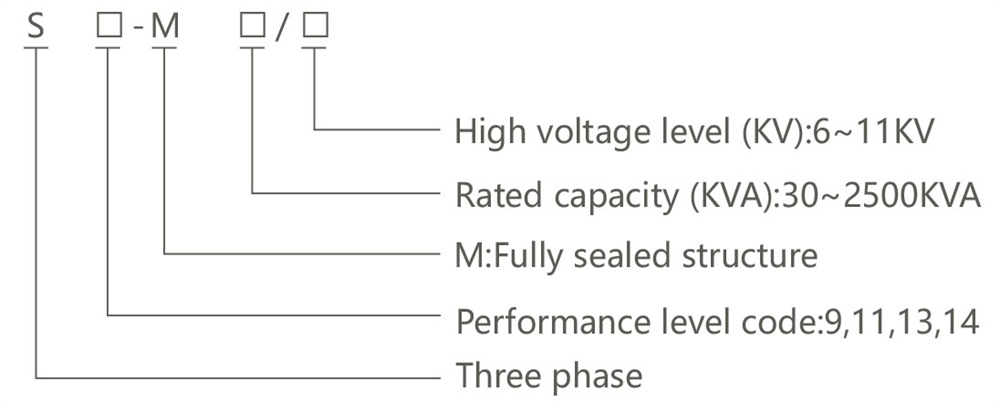

S9-M Series Oil-immersed Fully Sealed

The S9-M series three-phase oil-immersed transformer adopts a fully oil-filled, sealed corrugated oil tank. and the oil tank shell adapts to the expansion performance of the oil with its own elasticity and meets the heat dissipation requirements. It has the characteristics of high efficiency and low loss, which can save a lot of power consumption and operating costs, and is widely used in power plants, substations, industrial and mining enterprises, ports, airports and other environmental protection places.

Standard: IEC60076-1, IEC60076-2, IEC60076-3, IEC60076-5, IEC60076-10.

Conatct Us

Product Details

Selection

Operating conditions

1. Ambient temperature: maximum temperature: +40°C, minimum temperature: -25℃ .

2. Average temperature of the hottest month:+30℃, average temperature in the hottest year: +20℃ .

3. Altitude not exceeding 1000m.

4. The waveform of the power supply voltage is similar to a sine wave.

5. The three-phase supply voltage should be approximately symmetrical.

6. The total harmonic content of the load current shall not exceed 5% of the rated current.

7. Where to use: indoors or outdoors.

Features

1. The product has the characteristics of high efficiency, low loss, low noise, etc.

2. High mechanical strength, balanced ampere-turn distribution, and strong short-circuit resistance.

3. Low no-load and load loss.

4. Small size, reliable operation, long service life, and maintenance free.

Structure

■ Iron core:

● The iron core is made of high-quality, high-performance, high-permeability silicon steel sheet, with low no-load loss.

■ High/low voltage winding:

● The low-voltage winding of 500KVA and below is a layer type, and the new spiral type is used for 630KVA and above.

● It has the characteristics of high mechanical strength, balanced ampere turn distribution, and strong short-circuit resistance.

■ Fully sealed structure:

● The product is a fully sealed structure. The vacuum oil filling process is used for the transformer packaging, which completely removes the moisture of the transformer, ensures the isolation of the transformer oil from the outside air, prevents the aging of the oil, and improves the operation reliability of the

transformer.

■ Positioning structure:

● The product body has added a positioning structure to prevent displacement during transportation, and all fasteners are equipped with fastening nuts to ensure that the fasteners do not loosen during long-term operation of the product.

■ Oil tank:

● The oil tank adopts a corrugated oil tank.Simple process, high mechanical strength,good welding effect,not easy to leak,due to the strong fluidity of the oil, the heat dissipation capacity of the product is improved.

■ Other configuration:

● Equipped with pressure relief valve, signal thermometer, ensures the safe operation of the transformer.

S9-M 30~2500/10KV technical data

| Rated capacity (KVA) |

Voltage combination | Connection group label | No-load loss(W) | Load loss(W) | No-load curr (%) ent |

Short circuit impedance |

Dimensions | Total weight (kg) |

||||

| High voltage (KV) |

Tapping range |

Low voltage (KV) |

L | W | H | |||||||

| 30 | 6 6.3 10 10.5 11 |

±5 ±2×2.5 |

0.4 | Dyn11 Yyn0 Yzn11 |

130 | 630/600 | 2.3 | 4.0 | 745 | 530 | 890 | 280 |

| 50 | 170 | 910/870 | 2 | 790 | 560 | 940 | 365 | |||||

| 63 | 200 | 1090/1040 | 1.9 | 820 | 570 | 950 | 425 | |||||

| 80 | 250 | 1310/1250 | 1.9 | 850 | 580 | 1000 | 485 | |||||

| 100 | 290 | 1580/1500 | 1.8 | 900 | 620 | 1010 | 540 | |||||

| 125 | 340 | 1890/1800 | 1.7 | 880 | 630 | 1050 | 610 | |||||

| 160 | 400 | 2310/2200 | 1.6 | 950 | 690 | 1120 | 710 | |||||

| 200 | 480 | 2730/2600 | 1.5 | 990 | 730 | 1200 | 835 | |||||

| 250 | 560 | 3200/3050 | 1.4 | 1180 | 700 | 1200 | 970 | |||||

| 315 | 670 | 3830/3650 | 1.4 | 1230 | 760 | 1250 | 1125 | |||||

| 400 | 800 | 4520/4300 | 1.3 | 1260 | 800 | 1300 | 1310 | |||||

| 500 | 960 | 5410/5150 | 1.2 | 1400 | 900 | 1320 | 1530 | |||||

| 630 | Dyn11 Yyn0 | 1200 | 6200 | 1.1 | 4.5 | 1530 | 940 | 1350 | 1890 | |||

| 800 | 1400 | 7500 | 1 | 1580 | 1000 | 1420 | 2185 | |||||

| 1000 | 1700 | 10300 | 1 | 1770 | 1180 | 1450 | 2480 | |||||

| 1250 | 1950 | 12000 | 0.9 | 1920 | 1290 | 1430 | 3020 | |||||

| 1600 | 2400 | 14500 | 0.8 | 1990 | 1340 | 1620 | 3550 | |||||

| 2000 | 3000 | 17100 | 0.7 | 5.0 | 1950 | 1680 | 2100 | 4530 | ||||

| 2500 | 3300 | 23200 | 0.7 | 2020 | 1710 | 2100 | 5030 | |||||

Note 1: for transformers with rated capacity of 500kVA and below, the load loss values above the diagonal line in the table are applicable to the Dyn11 or Yzn11 coupling group, and the load loss values below the diagonal line are applicable to the Yyn0 coupling group.

Note 2: when the average annual load rate of the transformer is between 35% and 40%, the maximum operating eficiency can be obtained by using the loss value in the table.

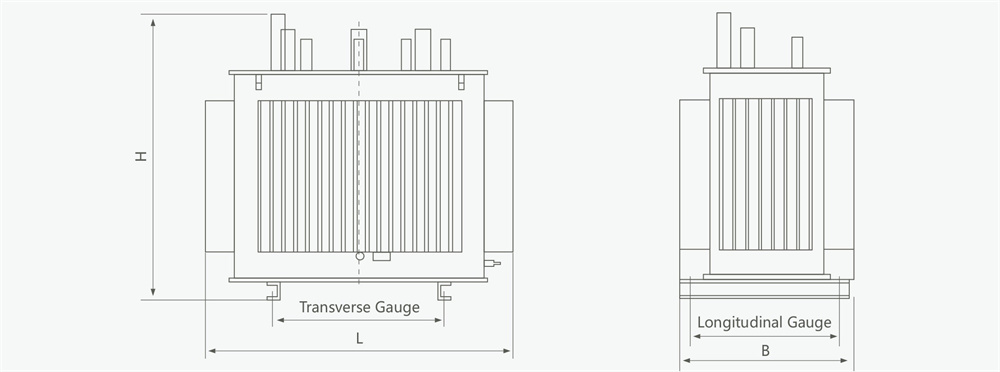

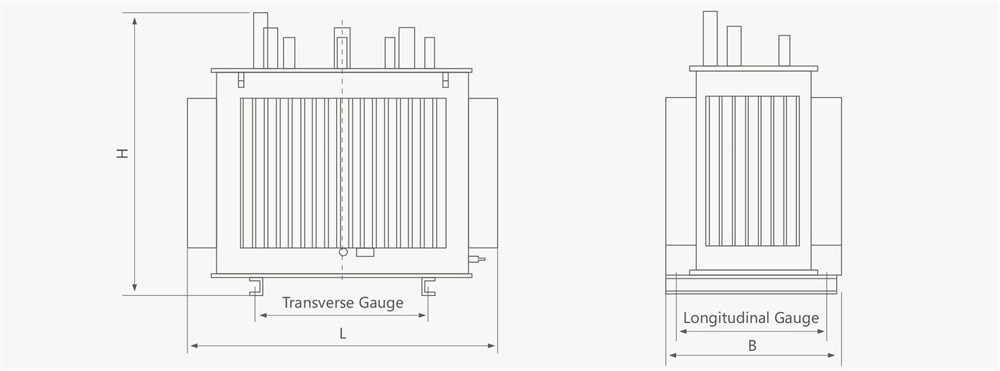

Overall and mounting dimensions(mm)

Note: The dimensions and weights provided are only for reference in design and selection. The final size and weight are subject to our product drawings.

S11-M 30~2500 /10KV technical data

| Rated capacity (KVA) |

Voltage combination | Connection group label | No-load loss(W) | Load loss(W) | No-load curr (%) ent |

Short circuit impedance |

Dimensions | Total weight (kg) |

||||

| High voltage (KV) |

Tapping range |

Low voltage (KV) |

L | W | H | |||||||

| 30 | 6 6.3 10 10.5 11 |

±5 ±2×2.5 |

0.4 | Dyn11 Yyn0 Yzn11 |

100 | 630/600 | 1.5 | 4.0 | 690 | 510 | 920 | 275 |

| 50 | 130 | 910/870 | 1.3 | 730 | 510 | 960 | 340 | |||||

| 63 | 150 | 1090/1040 | 1.2 | 750 | 550 | 1000 | 385 | |||||

| 80 | 180 | 1310/1250 | 1.2 | 790 | 620 | 1020 | 450 | |||||

| 100 | 200 | 1580/1500 | 1.1 | 790 | 700 | 1040 | 520 | |||||

| 125 | 240 | 1890/1800 | 1.1 | 840 | 800 | 1070 | 625 | |||||

| 160 | 280 | 2310/2200 | 1 | 1070 | 670 | 1130 | 695 | |||||

| 200 | 340 | 2730/2600 | 1 | 1140 | 750 | 1140 | 795 | |||||

| 250 | 400 | 3200/3050 | 0.9 | 1200 | 800 | 1190 | 955 | |||||

| 315 | 480 | 3830/3650 | 0.9 | 1300 | 860 | 1210 | 1085 | |||||

| 400 | 570 | 4520/4300 | 0.8 | 1380 | 900 | 1240 | 1290 | |||||

| 500 | 680 | 5410/5100 | 0.8 | 1450 | 950 | 1300 | 1590 | |||||

| 630 | Dyn11 Yyn0 | 810 | 6200 | 0.6 | 4.5 | 1500 | 970 | 1360 | 1850 | |||

| 800 | 980 | 7500 | 0.6 | 1660 | 1140 | 1400 | 2210 | |||||

| 1000 | 1150 | 10300 | 0.6 | 1690 | 1190 | 1530 | 2570 | |||||

| 1250 | 1360 | 12000 | 0.5 | 1760 | 1230 | 1600 | 3115 | |||||

| 1600 | 1640 | 14500 | 0.5 | 1800 | 1250 | 1660 | 3520 | |||||

| 2000 | 1940 | 18300 | 0.4 | 5.0 | 1930 | 1360 | 1490 | 4060 | ||||

| 2500 | 2290 | 21200 | 0.4 | 2080 | 1360 | 1570 | 5105 | |||||

Note 1: for transformers with rated capacity of 500kVA and below, the load loss values above the diagonal line in the table are applicable to the Dyn11 or Yzn11 coupling group, and the load loss values below the diagonal line are applicable to the Yyn0 coupling group.

Note 2: when the average annual load rate of the transformer is between 35% and 40%, the maximum operating eficiency can be obtained by using the loss value in the table.

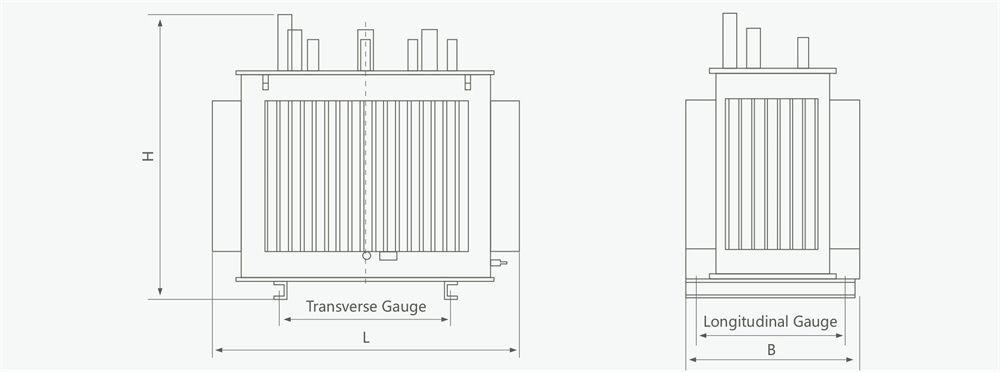

Overall and mounting dimensions(mm)

Note: The dimensions and weights provided are only for reference in design and selection. The final size and weight are subject to our product drawings.

S13-M 30~2500 /10KV technical data

| Rated capacity (KVA) |

Voltage combination | Connection group label | No-load loss(W) | Load loss(W) | No-load curr (%) ent |

Short circuit impedance |

Dimensions | Total weight (kg) |

||||

| High voltage (KV) |

Tapping range |

Low voltage (KV) |

L | W | H | |||||||

| 30 | 6 6.3 10 10.5 11 |

±5 ±2×2.5 |

0.4 | Dyn11 Yyn0 Yzn11 |

80 | 630/600 | 1.5 | 4.0 | 685 | 490 | 860 | 260 |

| 50 | 100 | 910/870 | 1.3 | 725 | 520 | 955 | 365 | |||||

| 63 | 110 | 1090/1040 | 1.2 | 750 | 535 | 970 | 415 | |||||

| 80 | 130 | 1310/1250 | 1.2 | 770 | 565 | 985 | 465 | |||||

| 100 | 150 | 1580/1500 | 1.2 | 800 | 595 | 1000 | 545 | |||||

| 125 | 170 | 1890/1800 | 1.1 | 815 | 670 | 1010 | 585 | |||||

| 160 | 200 | 2310/2200 | 1.1 | 1015 | 645 | 1055 | 695 | |||||

| 200 | 240 | 2730/2600 | 1 | 1020 | 650 | 1115 | 810 | |||||

| 250 | 290 | 3200/3050 | 1 | 1140 | 730 | 1120 | 930 | |||||

| 315 | 340 | 3830/3650 | 0.9 | 1195 | 785 | 1175 | 1075 | |||||

| 400 | 410 | 4520/4300 | 0.9 | 1265 | 855 | 1195 | 1255 | |||||

| 500 | 480 | 5410/5100 | 0.8 | 1325 | 915 | 1240 | 1435 | |||||

| 630 | Dyn11 Yyn0 | 570 | 6200 | 0.8 | 4.5 | 1465 | 960 | 1295 | 1880 | |||

| 800 | 700 | 7500 | 0.6 | 1515 | 995 | 1340 | 2145 | |||||

| 1000 | 830 | 10300 | 0.6 | 1605 | 1095 | 1460 | 2455 | |||||

| 1250 | 970 | 12000 | 0.5 | 1685 | 1145 | 1485 | 2840 | |||||

| 1600 | 1170 | 14500 | 0.5 | 1775 | 1225 | 1580 | 3310 | |||||

| 2000 | 1550 | 18300 | 0.4 | 5.0 | 1855 | 1265 | 1600 | 3960 | ||||

| 2500 | 1830 | 21200 | 0.4 | 1885 | 1305 | 1780 | 4980 | |||||

Note 1: for transformers with rated capacity of 500kVA and below, the load loss values above the diagonal line in the table are applicable to the Dyn11 or Yzn11 coupling group, and the load loss values below the diagonal line are applicable to the Yyn0 coupling group.

Note 2: when the average annual load rate of the transformer is between 35% and 40%, the maximum operating eficiency can be obtained by using the loss value in the table.

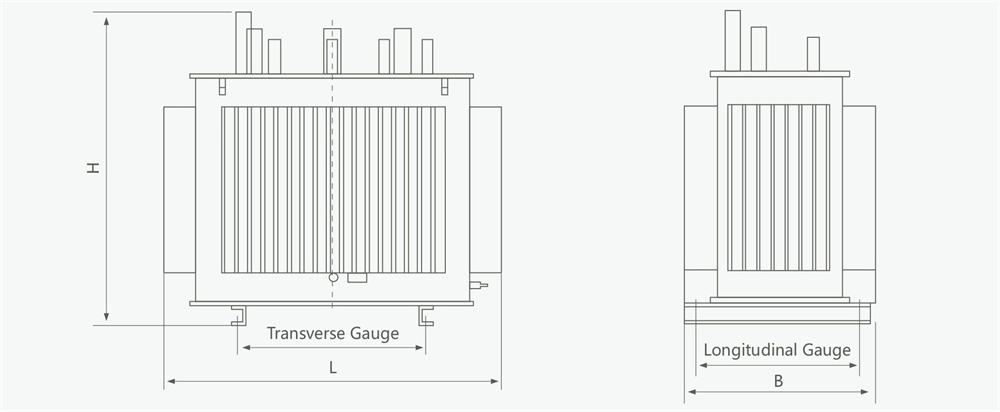

Overall and mounting dimensions(mm)

Note: The dimensions and weights provided are only for reference in design and selection. The final size and weight are subject to our product drawings.

S14-M 30~2500 /10KV technical data

| Rated capacity (KVA) |

Voltage combination | Connection group label | No-load loss(W) | Load loss(W) | No-load curr (%) ent |

Short circuit impedance |

Dimensions | Total weight (kg) |

||||

| High voltage (KV) |

Tapping range |

Low voltage (KV) |

L | W | H | |||||||

| 30 | 6 6.3 10 10.5 11 |

±5 ±2×2.5 |

0.4 | Dyn11 Yyn0 Yzn11 |

80 | 505/480 | 1.5 | 4.0 | 785 | 710 | 880 | 370 |

| 50 | 100 | 730/695 | 1.3 | 800 | 730 | 940 | 480 | |||||

| 63 | 110 | 870/830 | 1.2 | 815 | 720 | 970 | 535 | |||||

| 80 | 130 | 1050/1000 | 1.2 | 830 | 740 | 990 | 580 | |||||

| 100 | 150 | 1260/1200 | 1.1 | 875 | 790 | 1010 | 705 | |||||

| 125 | 170 | 1510/1440 | 1.1 | 875 | 770 | 1050 | 775 | |||||

| 160 | 200 | 1850/1760 | 1 | 935 | 820 | 1140 | 975 | |||||

| 200 | 240 | 2180/2080 | 1 | 995 | 870 | 1140 | 1140 | |||||

| 250 | 290 | 2560/2440 | 0.9 | 995 | 900 | 1180 | 1240 | |||||

| 315 | 340 | 3060/2920 | 0.9 | 1030 | 880 | 1250 | 1425 | |||||

| 400 | 410 | 3610/3440 | 0.8 | 1075 | 910 | 1270 | 1635 | |||||

| 500 | 480 | 4330/4120 | 0.8 | 1120 | 930 | 1320 | 1950 | |||||

| 630 | Dyn11 Yyn0 | 570 | 4960 | 0.6 | 4.5 | 1165 | 950 | 1350 | 2150 | |||

| 800 | 700 | 6000 | 0.6 | 1210 | 1050 | 1390 | 2515 | |||||

| 1000 | 830 | 8240 | 0.6 | 1520 | 1020 | 1450 | 2635 | |||||

| 1250 | 970 | 9600 | 0.5 | 1630 | 1090 | 1540 | 3210 | |||||

| 1600 | 1170 | 11600 | 0.5 | 1680 | 1150 | 1600 | 3905 | |||||

| 2000 | 1550 | 14600 | 0.4 | 5.0 | 1890 | 1300 | 1600 | 4130 | ||||

| 2500 | 1830 | 16900 | 0.4 | 1990 | 1360 | 1700 | 5250 | |||||

Note 1: for transformers with rated capacity of 500kVA and below, the load loss values above the diagonal line in the table are applicable to the Dyn11 or Yzn11 coupling group, and the load loss values below the diagonal line are applicable to the Yyn0 coupling group.

Note 2: when the average annual load rate of the transformer is between 35% and 40%, the maximum operating eficiency can be obtained by using the loss value in the table.

Overall and mounting dimensions(mm)

Note: The dimensions and weights provided are only for reference in design and selection. The final size and weight are subject to our product drawings.

CNC ELECTRIC GROUP ZHEJIANG TECHNOLOGY CO.,LTD

CNC ELECTRIC GROUP ZHEJIANG TECHNOLOGY CO.,LTD

Products

Products Projects

Projects Solutions

Solutions Service

Service News

News About CNC

About CNC Contact Us

Contact Us