-

Product Overview

-

Product Details

-

Data Download

-

Related Products

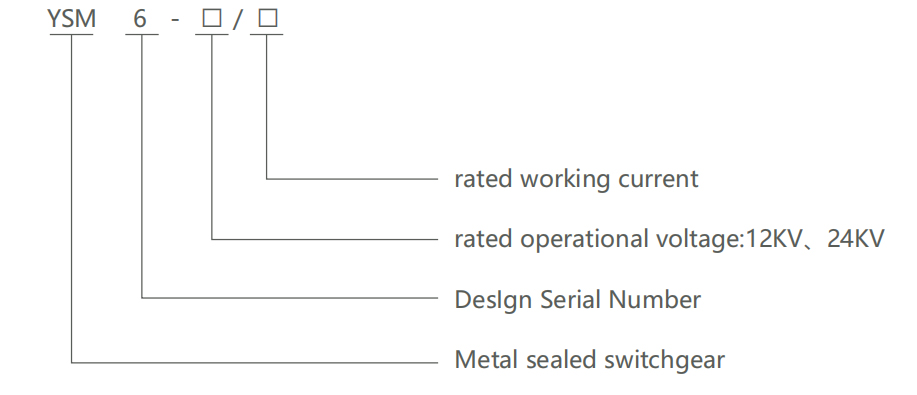

YSM6-12~24 Air-insulated RMU(Fixed Type)

YSM6-12/24 unit type SF6 RMU with SF6 load switch as main switch, for whole cabinet is suitable for electric distribution automation and compact also expandable metal close switchgear. It characters in its simple structure, flexible operation, reliable interlocking and convenient installation etc., which can provide the satisfactory technical projects both for different application occasions and users. With the adoption of sensor technology and the protection relay up to date, plus the advanced technology and flexible assembly project.

YSM6-12/24 unit type SF6 RMU can completely meet the requirement of continuously variable market. It can take self-produced SF6- 12/24 load break switch; Operational methods for the main switch inside ring main unit can be either manual or electric power driven. And it can meet the requirement of “Four Controls” when matched with FTU and RTU.

Conatct Us

Product Details

Selection

Operating conditions

1. Air temperature: Maximum temperature: +40℃; Minimum temperature:-5℃

2. Humidity: Monthly average humidity 95%; Daily average humidity 90% .

3. Altitude above sea level: Maximum installation altitude: 2000m

4. Ambient air not apparently polluted by corrosive and flammable gas, vapor etc.

5. No frequent violent shake

Features

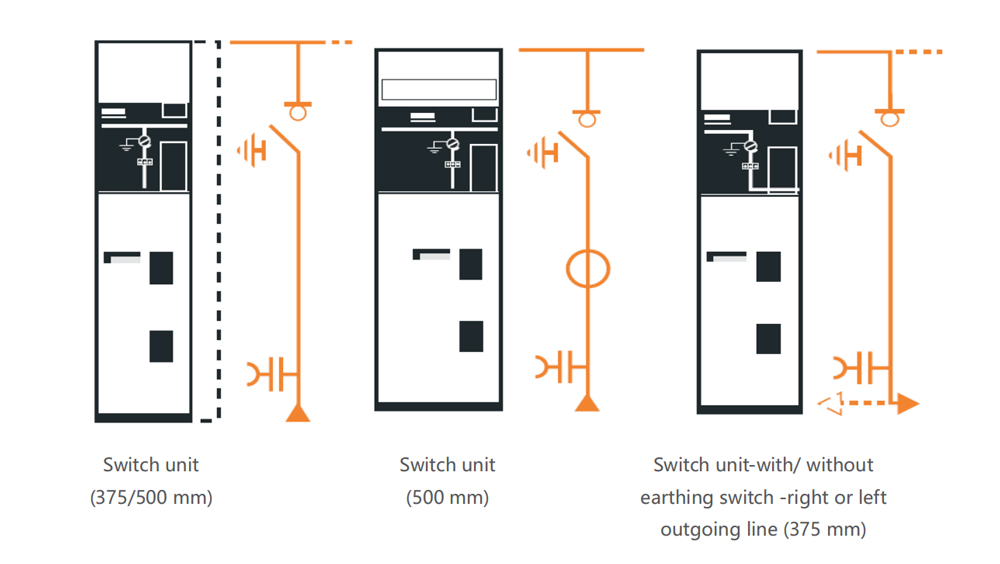

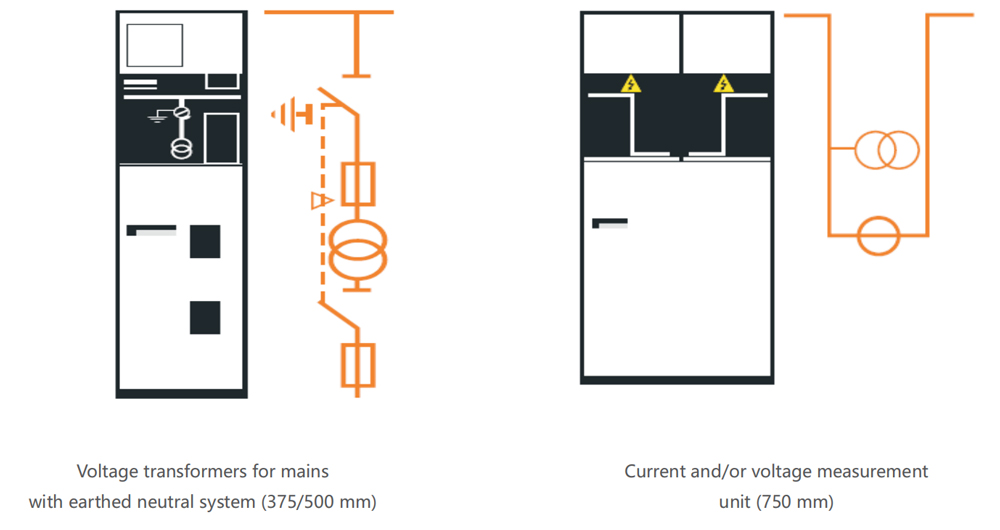

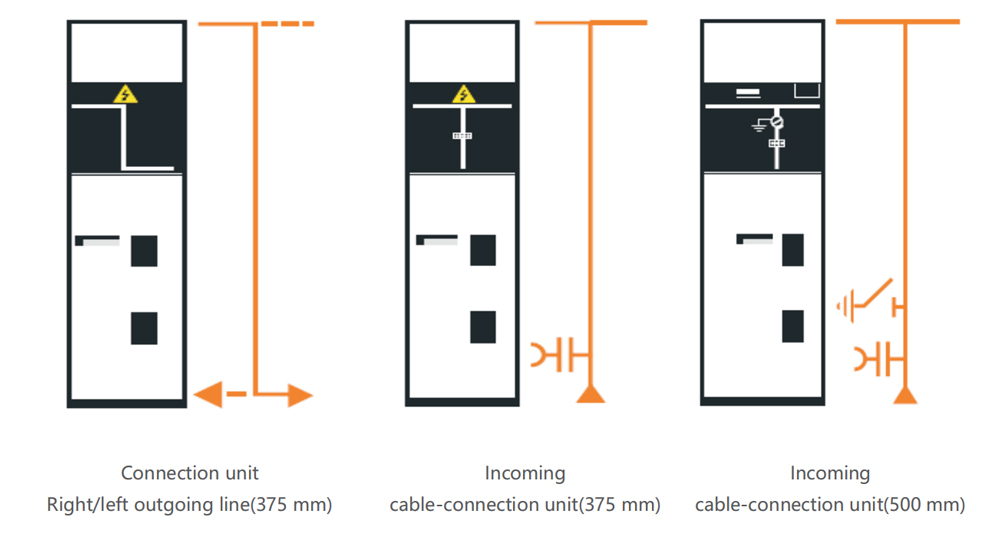

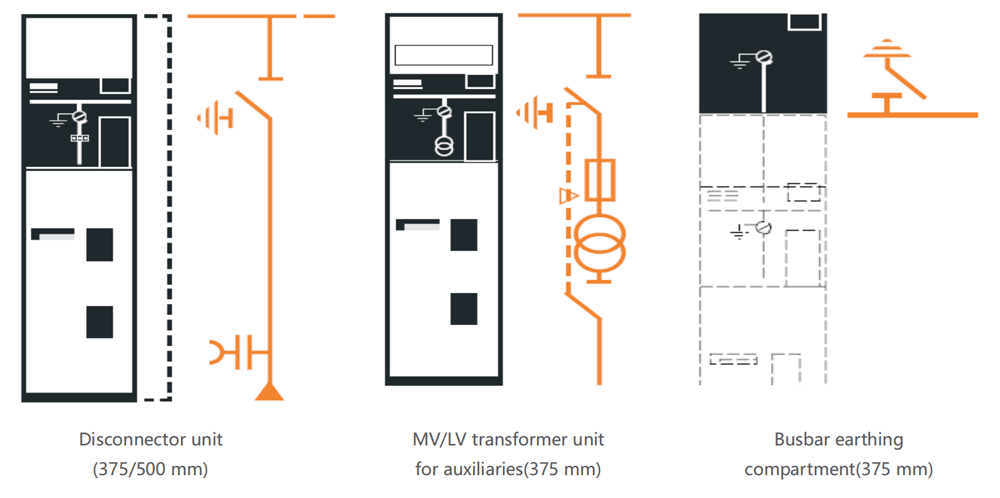

1. Incoming unit with switch disconnector(Load break switch) schemas With other extra components optional Outgoing unit with

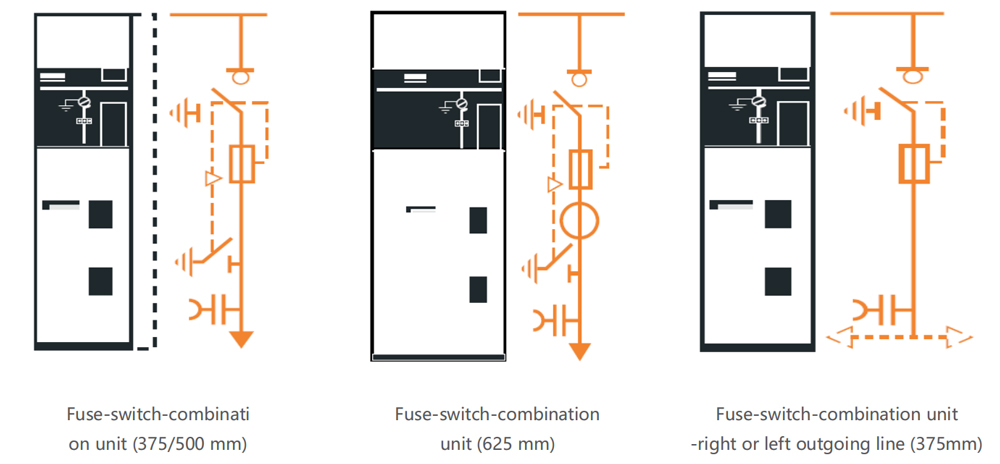

2. Fuse-switch protection schemas

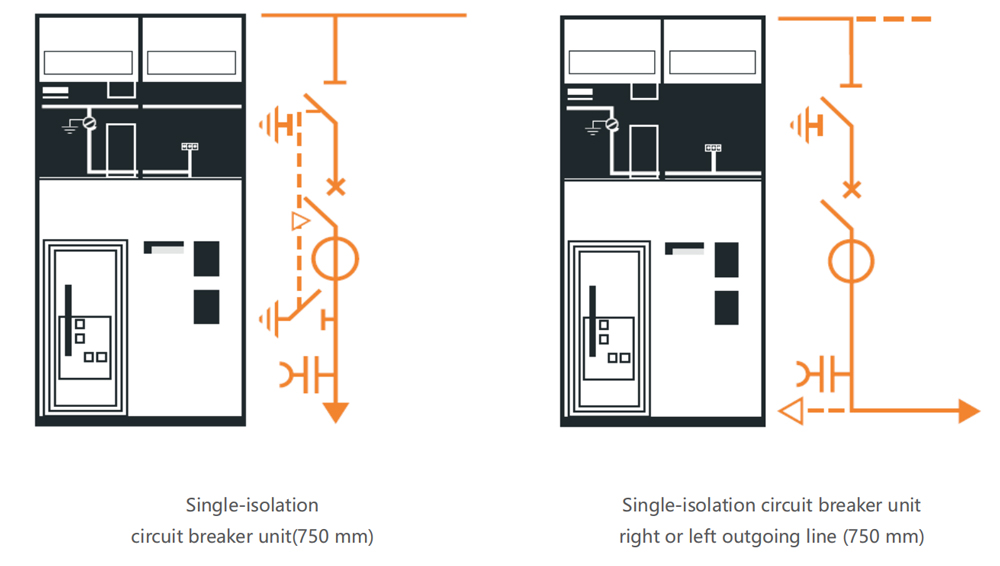

3. With other extra components optional Incoming/outgoing circuit breaker protection schemas With other extra components

4. optional MV metering schemas

5. With other extra components optional Casings (Bus bar Panel) schemasWith other extra components optional

6. Others

Technical data

| NO. | Items | Unit | Parameter | |

| 1 | Rated voltage | kV | 12 | 24 |

| 2 | Rated frequency | Hz | 50/60 | |

| 3 | Rated current | A | 630/800 | |

| 4 | 1min Power frequency withstand voltage | kV | 48 | 60 |

| 5 | Lightning impulse withstand voltage | kV | 75 | 125/150 |

| 6 | Rated short circuit breaking current (peak) | kA | 80 | 63 |

| 7 | Rated active load/close circuit breaking current | A | 63 | 50 |

| 8 | Rated transferring current | A | 1700 | 1200 |

| 9 | Rated short circuit making current (peak) | kA | 80 | 63 |

| 10 | Rated cable(line) charging breaking current | A | 50 and 10 | |

| 11 | Cable charge breaking current in earthing fault | A | 20 | 20 |

| 12 | Rated withstand current (peak) | kA | 80 | 63 |

| 13 | Short time withstand current (2s) | kA | 31.5 | 25 |

| 14 | Mechanism life | times | 2000 | |

Note: For short circuit breaking and peak current is based on Fuse plus combination.

For distribution switchboard schema

1. Switch disconnector

Note: Extra components for example lightning arresters or lower earthing switch is optional.

2. Fuse-switch protection

Note: Extra components for example lightning arresters or zero sequence CT is optional.

3. Circuit-breaker protection

Note: 1. For HV SF6 circuit breaker also with many types can be selected. It Is according to client’s requirement. ( SF1/Schneider, PF/Areva, etc.) Also Vacuum circuit breaker is also optional. (VD4/S-12/24 or SF6-12/24)

2. Other extra components for example Zero sequence CT is considering after communicated by our company.

4. MV metering

Note: Extra components for example lightning arresters or zero sequence CT is optional.

5. Casings (Bus bar Panel)

Note: Other extra components is optional (Disconnecting switch panel, Voltage transformer panel, etc.)

2. Fuse-switch protection

5 parts for the unit type SF6 ring main unit:

1. switch cubicle switch-disconnector and earthing switch in an enclosure filled with SF6 and satisfying “sealed pressure system ” requirements.

2. bus-bar cubicle all in the same horizontal plane, thus enabling later switchboard extensions and connection to existing equipment.

3. connection cubicle accessible through front, connection to the lower switch- disconnector and earthing switch terminals (IM cubicles) or the lower fuse- holders ( PM and QM cubicles). This compartment is also equipped with an earthing switch downstream from the MV fuses for the protection units.

4. operation mechanism, interlocking contains the elements used to operate the switchdisconnector and earthing switch and actuate the corresponding indications (positive break).

5. Low voltage cubicle (upper & lower enclosure structure) installation of a terminal block (if motor option installed), LV fuses and compact relay devices. If more space is required, an additional enclosure may be added on top of the cubicle.

6. Optional switch cubicles (IM) can also be fitted with: control motorisation; surge arrestors.

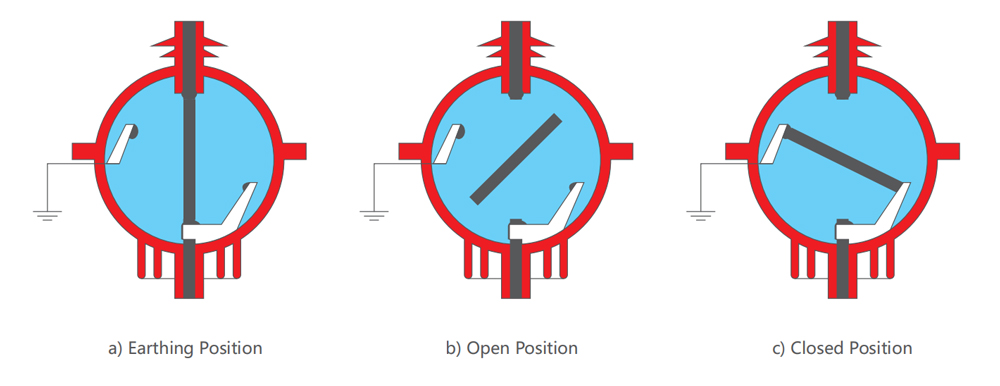

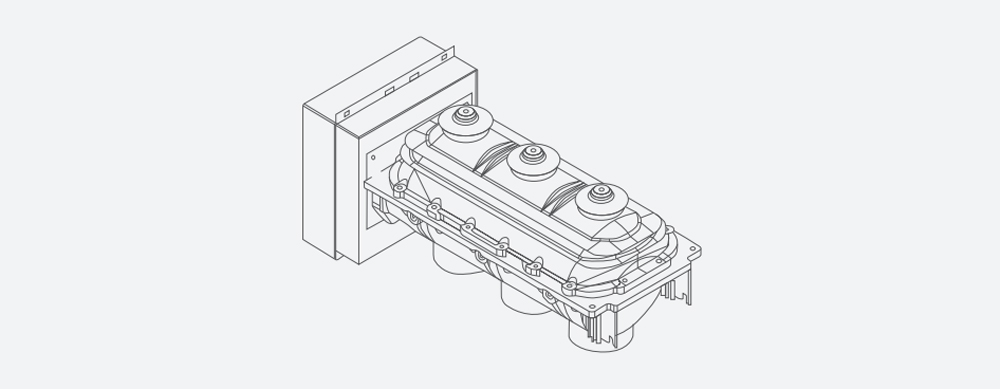

The three-phase rotary contact is installed in a gas chamber filled with SF6 gas and the relative pressure is 0.4bars. It has excellent operation performance with safety and reliability.

● Tightness:

The air chamber is filled with SF6 gas, which meets the standard requirements of "closed pressure system ", and the sealing performance has been checked and

inspected in the factory.

● Operational Safety:

1. The switch has three positions of "closed ", "open" and "grounded ", and has a locking function to prevent accidental operation. The contact is driven to rotate by the spring energy storage mechanism, which is not affected by human operation factors.

2. Has "break " and isolation functions.

3. The short-circuit making capacity of the SF6 grounding switch meets the standard requirements.

4. In the event of an accident, the pressure drops after the overpressured SF6 gas breaks through the safety diaphragm, and the gas will directly be sprayed into the back of the cabinet for safety.

Breaking Principle:

SF6 gas has excellent arc extinguishing performance. When the switch is opened, the relative movement between the arc and the gas will extinguish the arc. When the moving and static contacts are separated, the arc appears in the electromagnetic field generated by the permanent magnet, and the arc is elongated and extinguished when the current crosses zero by SF6 gas. The distance between the moving and static contacts is sufficient to withstand the recovery overvoltage. The system is simple and reliable, with minimal contact wear and long electrical life.

● Switchgear status indicator:

Fitted directly to the drive shaft, these give a defi nite indication of the contact ’s position. (appendix A of standard IEC 62271-102).

● Operating lever:

This is designed with an anti-refl ex device that stops any attempt to reopen the device immediately after closing the switch or the earthing disconnector.

● Locking device:

Between one and three padlocks enable the following to be locked:

● access to the switching shaft of the switch or the circuit breaker

● access to the switching shaft of the earthing disconnector

● operating of the opening release push-button. ●Simple and effortless switching

Mechanical and electrical controls are side by side on the front fascia,on a panel including the schematic diagram indicating the device ’s status (closed, open, earthed):

● Closed:

the drive shaft is operated via a quick acting mechanism,independent of the operator. No energy is stored in the switch, apart from when switching operations are taking place.

For combined switch fuses, the opening mechanism is armed at the same time as the contacts are closed.

● Opening:

the switch is opened using the same quick acting mechanism,operated in the opposite direction.

For a combined switch fuses unit, opening is controlled by:

● a push-button

● a fault.

● Earthing:

a specifi c control shaft enables the opening or closing of the earthing contacts. Access to this shaft is blocked by a cover that can be slid back if the switch is open but which remains locked in place if it is closed.

Voltage presence indicator

This device has integrated VPIS (Voltage Presence Indicating System) type lights, in conformity with IEC standard 61958, enabling the presence (or absence) of voltage to be checked on the cables.

Insensitivity to the environment

● An internal sealed enclosure, contains the active parts of the LBSkit

(switch, earthing disconnector). It is filled with SF6 in accordance with the defi nitions in IEC recommendation 62271-200 for “sealed pressure systems ”.

Sealing is systematically checked in the factory.

● Parts are designed in order to obtain optimum electrical fi eld distribution.

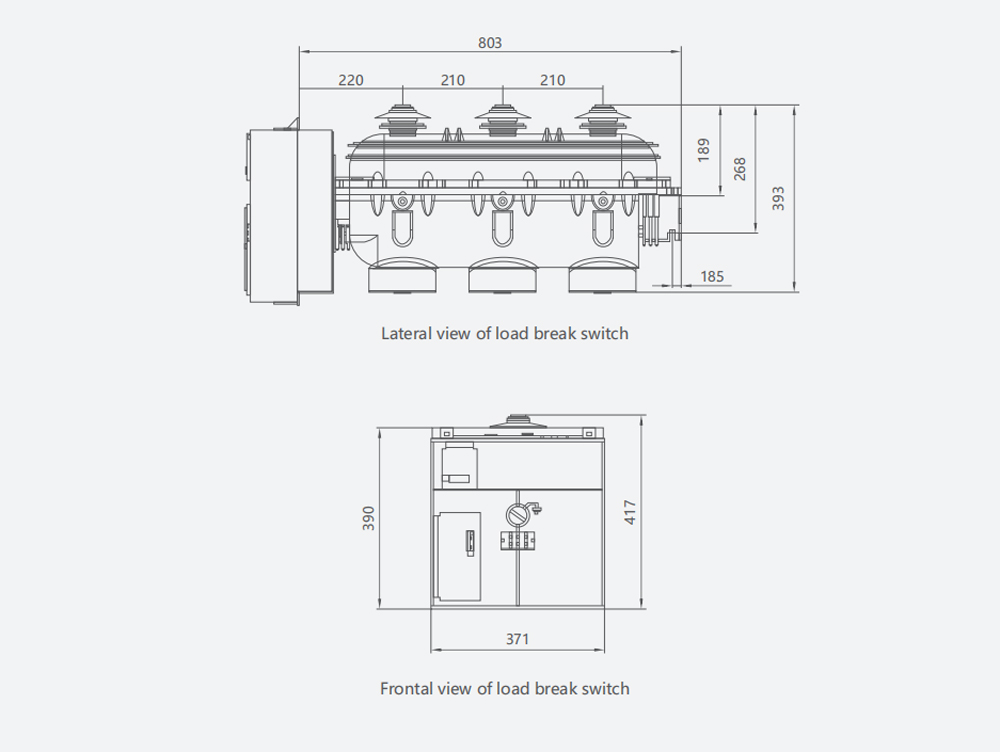

Overall and mounting dimensions(mm)

Matching Overall and mounting dimensions(mm) of SF6 load break switch-fuse combination Fig 1) SF6 load break switch without upper cubicle

Fig 2) Whole Load break switch outline

CNC ELECTRIC GROUP ZHEJIANG TECHNOLOGY CO.,LTD

CNC ELECTRIC GROUP ZHEJIANG TECHNOLOGY CO.,LTD

Products

Products Projects

Projects Solutions

Solutions Service

Service News

News About CNC

About CNC Contact Us

Contact Us